At National Fasteners, we specialize in manufacturing high tensile fasteners — bolts and nuts that deliver exceptional performance under the most demanding conditions. Whether you’re in construction, automotive, infrastructure, or heavy machinery, the strength of your project depends on the quality of every connection.

In this post, we’ll walk you through the quality standards, manufacturing process, and what to look for when choosing a trusted supplier for high tensile bolts and nuts.

🔩 What Are High Tensile Bolts and Nuts?

High tensile bolts and nuts are fasteners made from carbon steel or alloy steel, designed to endure high stress without stretching or breaking. Common grades include:

8.8 (Medium carbon steel, quenched & tempered)

10.9 and 12.9 (Alloy steel, heat-treated for greater strength)

These fasteners are widely used in:

Structural steel joints

Automotive engines and chassis

Wind turbines and energy installations

Bridges, towers, and heavy machinery

Looking for high tensile bolts in bulk? ➡️ Browse our full range of high tensile fasteners (insert product category page link)

⚙️ Our Manufacturing Process: Built for Strength

At National Fasteners, we follow a strict, ISO 9001:2015-certified manufacturing process to ensure every fastener meets global performance and safety standards.

1. Material Selection

We source only high-grade alloy and carbon steel, with mill certifications to match global specifications like IS 1367, DIN 933, and ASTM A325.

2. Forging & Forming

Using state-of-the-art cold and hot forging techniques, we shape fasteners while preserving grain flow and structural integrity.

3. Heat Treatment

Our heat treatment facilities are calibrated to achieve optimal tensile strength and hardness through quenching and tempering, essential for grades 10.9 and 12.9.

4. Precision Thread Rolling

We use thread rolling, not cutting, to maintain material strength and dimensional accuracy.

5. Protective Coating

Depending on your application, we offer:

Zinc plating

Hot-dip galvanizing

Black oxide

Geomet or Dacromet coatings (ideal for corrosion resistance)

6. Rigorous Testing & Inspection

Every lot is tested in-house for:

Tensile strength and hardness

Thread tolerance

Corrosion resistance (Salt Spray Test)

Dimensional and visual inspection

Our quality control lab complies with ISO 17025 testing standards.

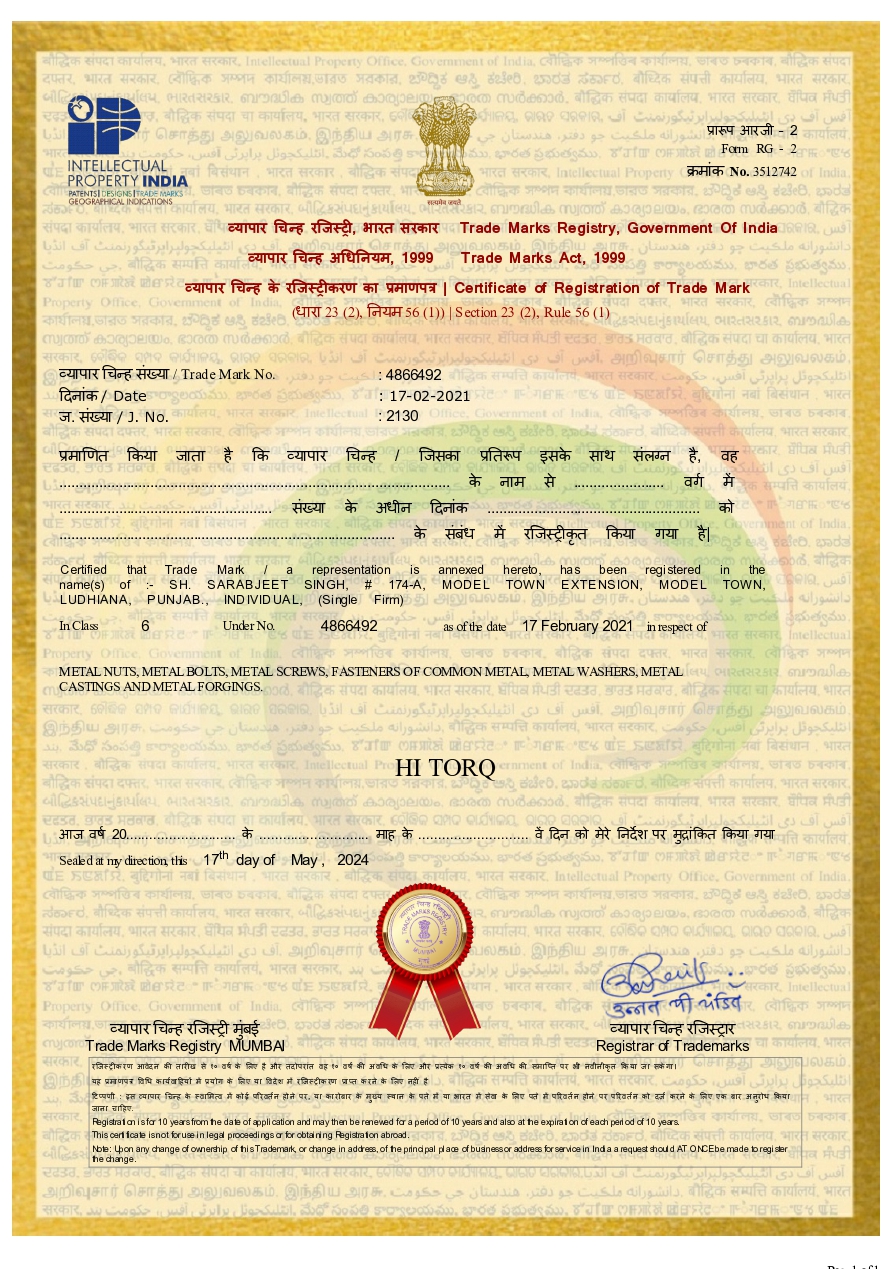

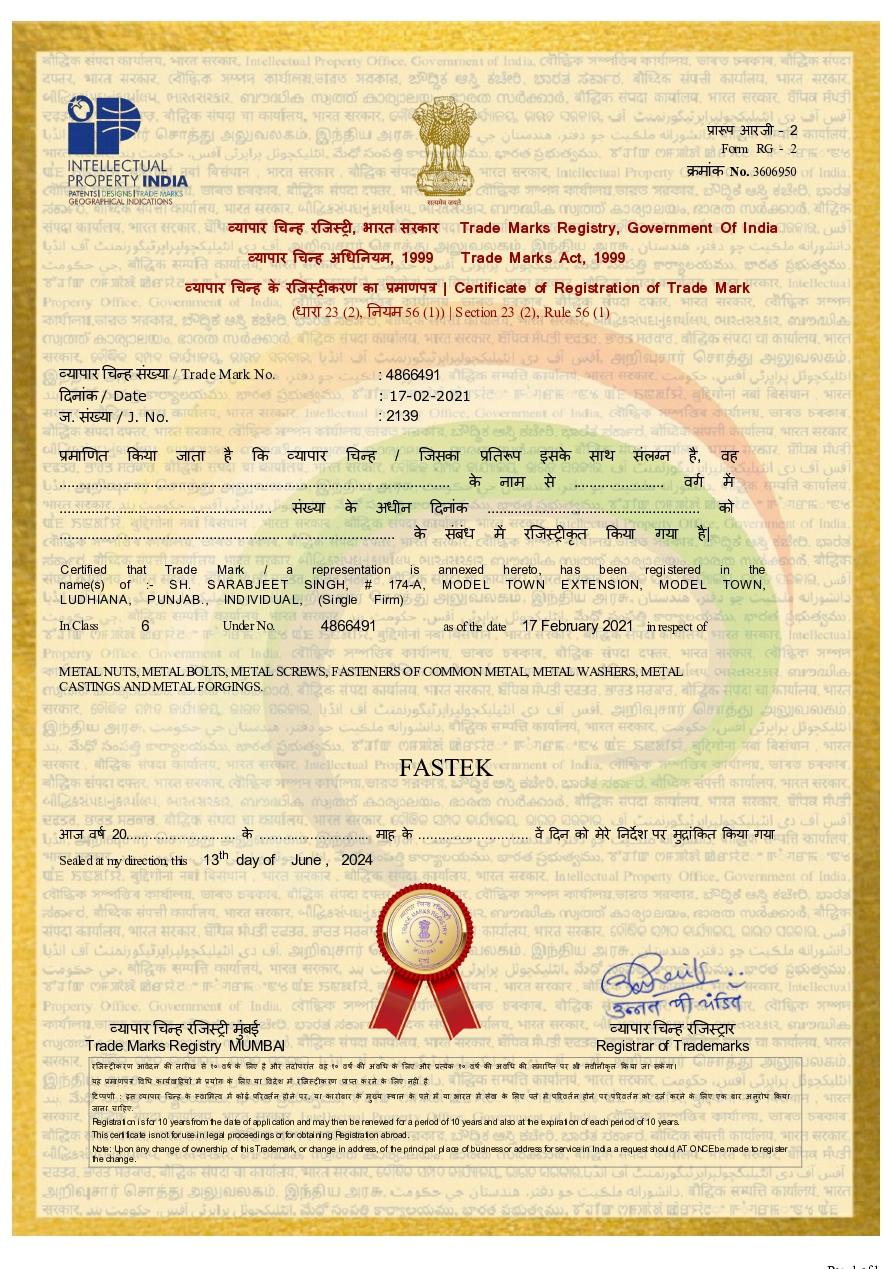

✅ Key Standards We Follow

We manufacture fasteners to the following international standards:

| Standard | Description |

|---|---|

| ISO 898-1 | Mechanical properties of bolts, screws, studs |

| DIN 933 / 931 | Hex bolts, full and partial thread |

| ASTM A325 / A490 | Structural bolts for heavy-duty applications |

| IS 1363 / IS 1367 | Indian standards for high tensile fasteners |

🛠 Why Standards Matter

Safety First – Prevent critical failures in high-load applications

Global Compatibility – Standard sizing makes replacements easy

Project Approval – Certified fasteners meet third-party inspections

Customer Confidence – Proven reliability builds long-term trust

💼 Why Choose Us?

✅ Over 47+ years of manufacturing expertise

🏭 ISO 9001:2015 certified facility

📦 Bulk supply, custom packaging & private labeling available

🌍 Serving clients across the Globe

🛒 Ready stock for fast dispatch

Looking for custom sizes or grades? ➡️ Request a Quote

📞 Let’s Build Stronger Together

When quality can’t be compromised, trust National Fasteners for precision-engineered, high tensile bolts and nuts. Contact our team today to discuss your project needs or get a sample.

👉 Contact Us | 📧 sales@nationalfasteners.com | 📞 +91 70093 08799